Previous seal studies relied heavily on ‘intuition and costly experiments’

Columbus, Ohio (March 7, 2012) – An Akron researcher is designing computer prediction models to test potential new docking seals that will better preserve breathable cabin air for astronauts living aboard the International Space Station and other NASA spacecraft.

|

| Nicholas Garafolo |

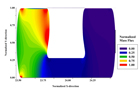

Garafolo recently analyzed a two-piece elastic silicone – or elastomer – seal, using the IBM 1350 Glenn computer cluster at the Ohio Supercomputer Center (OSC). His model simulated air leakage through the elastomer, taking into account the effects of gas compressibility and variable permeability.

“Recent advances in both analytical and computational permeation evaluations in elastomer space seals offer the ability to predict the leakage of space seals,” said Nicholas Garafolo, Ph.D., a research assistant professor in the College of Engineering at The University of Akron (UA). “Up until recently, the design of state-of-the-art space seals has relied heavily on intuition and costly experimental evaluations. My research evaluated the performance of the compressible permeation approach on a space seal candidate.”

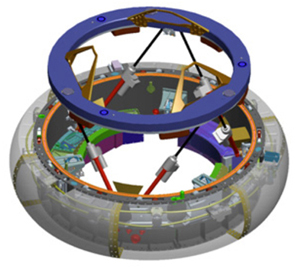

Garafolo serves on a research team tasked with testing polymer/metal seals being considered for future advanced docking and berthing systems. The university researchers work with partners in Cleveland, Ohio, at NASA’s Glenn Research Center, which is responsible for developing the main interface seals for the new International Low Impact Docking System (iLIDS).

“For many years, Ohio industry has invested heavily in the aviation, aerospace and manufacturing sectors, which naturally led OSC to focus a portion of its computational resources on the field of advanced materials,” said Ashok Krishnamurthy, interim co-executive director of the center. “Dr. Garafolo’s work is an excellent example of how modeling and simulation often allows scientists to analyze materials in ways not possible through simple observation or physical experimentation.”

NASA has been developing low-impact docking seals for manned missions to the International Space Station, as well as for future exploratory missions. Common to all docking systems, a main interface seal is mated to a metallic flange to provide the gas pressure seal.

“The two-piece seal system, for which experimental studies of seal performance are well documented, utilizes two elastomer bulbs, connected with a web and retained with a separate metallic ring,” Garafolo explained. “Baseline referent leak rate experiments were performed with a multitude of pressure differentials. The prediction method consisted of a computational analysis of referent geometry with temperature and pressure boundary conditions.”

To establish an analytical understanding of space seal leakage and construct their computational prediction tool, Garafolo and his colleagues modeled how air leaked into and through the elastomer seal, while taking into account the effects of gas compressibility and the variability of permeation on air pressure. The research team’s first evaluations showed significant correlations between the experimental values and the computer modeled results.

For pressure differentials near operating conditions, the leak rates determined by the model accurately reflected the experimental results, within the bounds of uncertainty. For pressure differentials exceeding normal operating conditions, the differences between the experimental results and computational numbers were not quite as close, as expected. The larger differences in the leak rates, however, were attributed to extrapolation errors of the model parameters.

Garafolo and colleague Christopher C. Daniels, Ph.D., UA associate research professor in the College of Engineering, authored the paper, “An Evaluation of the Compressible Permeation Approach for Elastomeric Space Seals.” It recently was published in the proceedings of the 50th Aerospace Sciences Meeting of the American Institute of Aeronautics and Astronautics, held in Nashville, Tenn., in January. The study was based upon work supported by NASA and through an allocation of computing time from OSC.

The Ohio Supercomputer Center (OSC), a member of the Ohio Technology Consortium of the Ohio Board of Regents, addresses the rising computational demands of academic and industrial research communities by providing a robust shared infrastructure and proven expertise in advanced modeling, simulation and analysis. OSC empowers scientists with the vital resources essential to make extraordinary discoveries and innovations, partners with businesses and industry to leverage computational science as a competitive force in the global knowledge economy, and leads efforts to equip the workforce with the key technology skills required to secure 21st century jobs. For more, visit www.osc.edu.

The Advanced Aerospace Seals Research group in the College of Engineering at The University of Akron and other partner locations focuses on the development of advanced aerospace seal technologies for the National Aeronautics and Space Administration’s Low Impact Docking System relevant for future space missions. For more, visit coel.ecgf.uakron.edu/~asdev/.